There are over 660 water treatment facilities located in Australia now. Managing a complex operational background in these plants is not something that should be taken lightly as it affects the environment of the whole country. Due to the compounded nature of the field, administrators of the water treatment plants have started moving towards new technological solutions. One of them is the ‘Sensor technology’ for sure. The implementation of sensors has been revolutionising the way water treatment facilities are handling their assets. As its name suggests, this technology can ‘sense’ everything from small irregularities to large-scale abnormalities.

In this article, you will learn everything about the employment of sensors in the asset management of water treatment plants, while exploring their challenges and how the latter provides the best answers for them.

What is Sensor Technology?

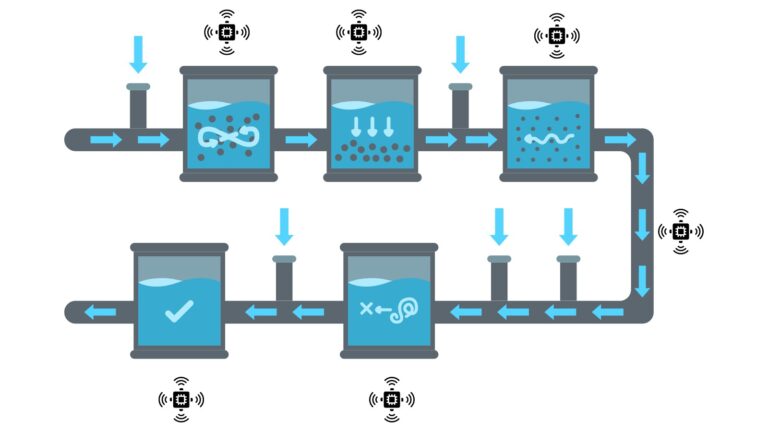

Sensors come in a broad variety of forms, but at their core, they are devices that identify a measuring object’s feature amount and translate it into a readable signal that can be read by an instrument. Simply put, sensing technology is a field of technology that uses sensors to gather data by identifying amounts of physical, chemical, or biological properties and transforming them into readable signals.

Sensor technology and its many applications are continually changing to keep up with technological breakthroughs and commercial demands. There are sensors available that measure a wide range of physical characteristics, including heat, pressure, and distance. Also, sensors can do a lot when combined with other powerful technologies like the Internet of Things (IoT) and data analytics.

Key Asset Management Challenges in Water Treatment Facilities

Ageing Infrastructure

The challenge of ageing equipment significantly impacts water treatment plants. Many facilities rely on outdated systems that require frequent repairs, leading to increased expenses and potential operational disruptions. The need for more frequent fixes and replacements escalates costs and diverts resources from other essential aspects.

Furthermore, these aged components might no longer comply with regulations or effectively integrate with newer, more efficient methods. Consequently, water treatment plants may struggle to fulfil their primary mission of providing clean and safe water to communities. The issue extends beyond financial implications, affecting the plant’s ability to function efficiently, adhere to standards, and embrace advancements in technology for optimal water treatment performance.

Data Integration

Data Integration presents a significant hurdle in managing water treatment assets. Bringing together information from different equipment can be difficult because water treatment systems use a variety of equipment and technologies. This diversity can cause problems with getting data to work well together. Compatibility issues often arise, making it tough to effectively use the collected data.

Gathering and integrating data from various assets can be complex due to the diverse nature of equipment and systems used in water treatment. Compatibility issues can hinder effective data utilisation. Overcoming these challenges demands streamlined data collection methods and integration strategies that ensure seamless communication between various asset components.

Prediction of Equipment Failures

Predicting when machines might break or need fixing is tough. Using predictive maintenance well needs the right facts, careful data study, and special skills. Figuring out when equipment might fail or need care is hard because many things affect how they work. Successful predictive maintenance means collecting exact data, using smart tools to understand it, and having experts who know a lot about water treatment systems.

Getting predictions right helps make plans to fix things better, reduce the time they are not working, and keep water treatment going smoothly. In short, good guessing leads to better-fixing plans, fewer interruptions, and water treatment plants working well all the time.

Difficult to Inspect Infrastructure

Some assets are situated in intricate environments, making assessments difficult. Employees often encounter hazardous conditions when inspecting these locations. The complexity of certain settings, such as confined spaces or elevated structures, complicates routine checks. Workers face risks like exposure to chemicals or falls while assessing assets.

Accessing remote or hard-to-reach areas adds further complexity. To overcome this, innovative inspection methods, like remote sensors or drones, are crucial. These technologies allow safer assessments while reducing operational disruptions. Addressing the difficulty of inspecting challenging infrastructure enhances safety for employees and ensures the efficient maintenance of water treatment assets.

How Sensors Ensure Optimised Water Treatment Asset Conditions

Continuous Condition Monitoring

This robust technology plays a vital role in managing water treatment assets through continuous condition monitoring. Sensors keep an eye on things like pumps, valves, and filters all the time. This helps catch problems early, like strange things happening or leaks, so they can be fixed quickly before they become big issues.

For instance, if a pump is not working right, the sensor can signal it right away. This prevents expensive breakdowns and keeps the treatment process running smoothly. These sensors give real-time updates on how everything’s working, making sure nothing goes wrong unnoticed and saving time and money on repairs.

Real-Time Data-driven Insights

This cutting-edge technology greatly aids water treatment asset management by providing real-time data-driven insights. Sensors gather and send information about how assets, water quality, and operations are doing. This info is studied to find patterns, improve how things work, and make smart choices for the plant to run better.

For example, sensors can tell if water quality is changing or if an asset is not working right. This helps operators figure out what’s going on and what needs fixing. These insights make sure everything is running well, improve how things are done, and help water treatment plants deliver clean water efficiently.

Making Way to Predictive Maintenance

This is one of the mainstream technologies that pave the path for predictive maintenance in water treatment asset handling. Sensors keep a constant watch on how assets are doing. They collect data that algorithms study to guess when equipment might have issues. This is called predictive maintenance which has gained immense popularity in asset-related handling operations.

When sensors notice something is about to go wrong, maintenance teams can step in quickly. This prevents unexpected breaks and keeps the water treatment plant running smoothly. Instead of waiting for things to break, predictive maintenance helps fix them before they become big problems. This technology saves time, and money, and ensures that water treatment operations keep flowing efficiently.

Inspection through Remote Monitoring

As we mentioned in the above sections, water treatment facilities consist of various complex infrastructures. Sensors make it possible to check assets from afar, cutting down the need for people to be physically present. This is super useful for assets in faraway or hard-to-reach places. Instead of sending someone on-site, sensors provide real-time updates on how things are doing.

This saves time and resources, making inspections more efficient. For example, if a sensor notices something wrong with a valve in a remote area, operators can act without travelling there. This technology makes sure assets are checked regularly, even in tricky locations, keeping water treatment operations running smoothly.

Contributing to Efficiency Optimisation

As a result, the latter enhances water treatment asset management by boosting efficiency. Sensors highlight inefficiencies in the treatment process by tracking factors such as flow rates and chemical levels.

Operators can then tweak operations to use resources more effectively and save energy. This data-driven approach optimises the water treatment process, ensuring resource efficiency and reduced environmental impact.

Revolutionise Water Treatment Performance with Technology

As you have read in the article, the whole water treatment asset operations are being revolutionised by the impact of sensor technology. Now it has become a software solution that is a necessity in this industry. However, if you are considering purchasing software like this, our friendly advice is to do thorough research on the functionalities it provides prior to making a decision.