The water and wastewater industries have to be equipped with the latest technologies as well as tools in the market if they need to maintain a competitive edge in today’s world. However, choosing the right tools is not as easy as you think, since it requires expert knowledge. Air compressors are such equipment that is highly valuable in the water and wastewater industries in Australia, and they see a really good demand in the market.

What exactly are these air compressors? What are the factors you need to check before buying a new air compressor? Well, this article is all about this.

What are Air Compressors?

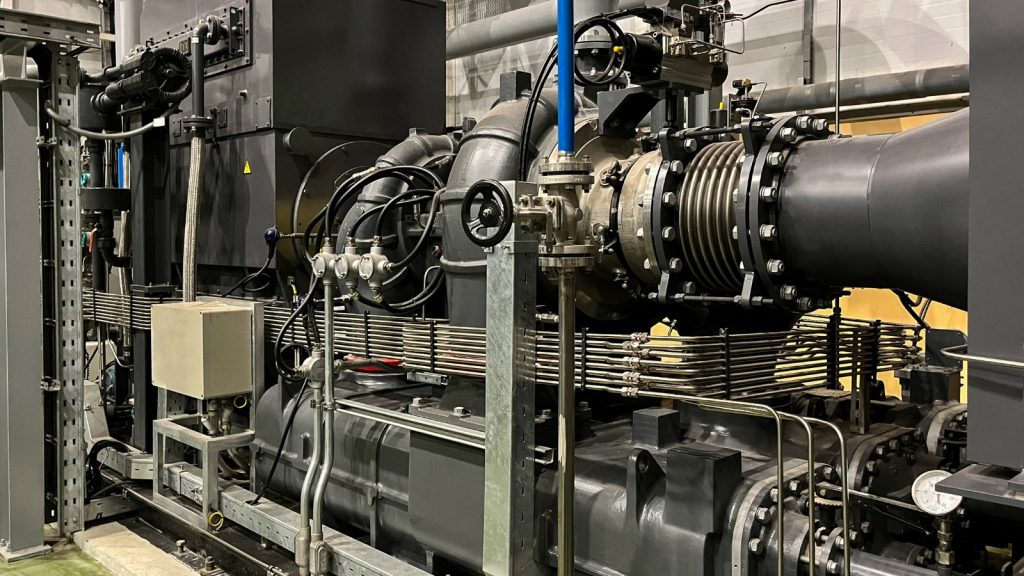

- Air compressors are mechanical devices that increase the pressure of air by reducing its volume.

- They work by compressing atmospheric air and storing it in a tank for later use. Air compressors are essential in the water and wastewater industry for various applications.

- The number one reason is that they are used for aeration in wastewater treatment plants, where compressed air is pumped into water to facilitate the growth of aerobic bacteria, which break down organic pollutants. Since air compressors power pneumatic valves and actuators in water treatment processes, they mutually aid in the control and regulation of water flow and pressure.

- On the other hand, they are used in pumping stations to maintain proper pressure levels in pipelines and assist in dredging operations to remove sediment buildup.

Main Factors to Consider When Buying Air Compressors

Type of Air Compressor

Before purchasing an air compressor, it is necessary to consider the type of compressor that best suits your application.

There are different types available, including reciprocating piston compressors, rotary screw compressors, and centrifugal compressors.

Obviously, each type has unique characteristics and capabilities. Compressor types differ in terms of factors like duty cycle, flow rate, and output pressure, which affect which ones are best suited for a certain purpose.

Let us put it this way. Reciprocating piston compressors are ideal for intermittent use and low- to medium-pressure applications, while rotary screw compressors are better suited for continuous operation and higher pressure requirements. So, it is vital to check the type of air compressor before buying it.

Intended Use

You can use air compressors for various purposes. Whether for home use, professional applications, industrial tasks, or specific functions, each application requires a compressor with specific capabilities and features.

If you understand the primary purpose, it means you ensure that the chosen compressor meets the requirements in terms of power, pressure, airflow, durability, etc.

This means you are going to receive efficient performance and suitability for the intended application.

Tank Size

Why is this fact so important? That is because it directly impacts the amount of compressed air available for use.

A bigger tank is required to retain a greater volume of compressed air for continuous or high-demand applications. This ensures steady airflow, reduces the likelihood of frequent cycling, and decreases pressure.

When decreasing the number of times the motor begins and stops, a larger tank makes it possible for the compressor to run more effectively. On the other hand, you can improve its lifespan and performance.

Power Source

This is something you must keep in mind when purchasing an air compressor. Do you know why? It is important for you to determine whether you need an electric-powered or gas-powered compressor based on your specific requirements.

For example, electric models are suitable for indoor use due to their quieter operation and lack of emissions. This is what makes them ideal for residential settings or enclosed workspaces. On the other hand, gas-powered compressors offer portability and are better suited for outdoor or remote locations where access to electricity may be limited.

They are adaptable for use on building sites, remote work locations, and locations without dependable power supplies due to their capacity to function without requiring electrical outlets.

Portability

This is crucial, especially if mobility is required for your intended use.

You are supposed to assess the weight, size, and presence of features like wheels or handles to ensure easy transportation between job sites or work areas.

Portable air compressors offer convenience and flexibility for technicians who need to move the unit frequently.

Whether it is for construction projects, automotive repairs, or home improvement tasks, the ability to transport the compressor effortlessly enhances productivity and efficiency.

CFM (Cubic Feet per Minute) Rating

Have you ever heard of this? The CFM rating is a critical factor to consider when purchasing an air compressor, as it directly affects its ability to power pneumatic tools effectively.

Let us explain how. CFM indicates the airflow rate produced by the compressor, which is crucial for maintaining consistent tool performance. It verifies if the compressor can provide enough air to run pneumatic tools as efficiently as possible.

It is crucial to confirm that the compressor’s CFM rating equals or surpasses the specifications of the tools you want to use in order to prevent performance problems like impaired power or inefficient tool operation.

PSI (Pounds per Square Inch) Rating

This directly influences the pressure at which the compressor delivers air to pneumatic tools or equipment.

PSI measures the force exerted by the compressed air and determines its ability to perform specific tasks effectively. The maximum pressure needs of your machinery or tools must be aligned with the PSI rating of the compressor to guarantee compatibility and effective operation.

If this is not done, there could not be enough pressure applied for the intended use, which might cause inefficiencies, poor performance, or even perhaps harm the instruments.

This is why we emphasise that you select a compressor with the appropriate PSI rating because you can guarantee optimal performance and safety while achieving desired results in your pneumatic tasks.

Noise Level

This is extremely vital if you plan to use your air compressor in noise-sensitive environments. You know that excessive noise can disrupt surroundings, causing inconvenience or even violating noise regulations, which Australia places a high value on.

As a result, it is critical to evaluate the compressor’s noise fabrication and choose low-noisy versions by choosing those with lower decibel values.

Selecting a quieter compressor can help you ensure a more comfortable working environment by reducing noise disruptions to you and those around you inside the water treatment plant.

Maintenance Requirements

It would be quite beneficial if you could evaluate factors such as oil changes, filter replacements, and general servicing needs to understand the ongoing upkeep necessary for the compressor.

Selecting a machine with easily accessible parts and straightforward maintenance guidelines makes regular chores easier, encouraging timely upkeep and extending the compressor’s life. You need to keep in mind that ignoring maintenance can cause expensive repairs or replacements due to early wear, decreased efficiency, and possible failures.

If you think about this, consider maintenance needs upfront, and select a compressor with user-friendly maintenance features, you can optimise its longevity and reliability while minimising downtime.

Brand Reputation and Warranty

This is essential for ensuring product quality, reliability, and customer support. Good brands tend to be linked to excellent workmanship, robust design, and consistent performance.

In addition, reputable brands typically offer comprehensive warranties, providing assurance and protection against manufacturing defects or premature failures.

When you choose a trusted brand with a solid reputation and a robust warranty policy, you can have peace of mind knowing that you are investing in a high-quality product. This means less worries, for sure!

Successfully Avoiding Problems with Air Compressors

As much as you place much attention on the reliability of air compressors within the water and wastewater industries, it is equally important to align their mechanisms with the right technologies. Whether it is AI, Digital Twin, IoT, or Predictive Analytics, you should go for machinery that can be easily integrated with such noble technologies.