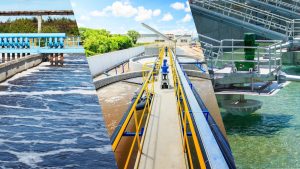

Reticulation of water refers to the distribution of water. This specifically becomes more relevant when it comes to recycling water which is redistributed back to the public for specific purposes. The sewage of any household in a given region is generally connected to a common reticulation system. Canals, which are used to transport water from one place to another, are used for this purpose. With the increasing population, the need to provide water to everyone has become a dire reality in Australia. When considering the water percentage on Earth, out of 71 per cent, there is only 1.2 per cent of freshwater. Two-thirds of the remaining is in glaciers and ice caps, whilst groundwater accounts for the remaining 30 per cent. Due to this, sustainable recycling efforts need to be implemented. In other words, humans cannot afford to waste water, so assets in the water industry must be in top-notch condition. Failing to ensure this would mean that water is wasted as it is contaminated, leaked or reticulated in the wrong quantities to different parts of the nation. This article will explain how reticulation in water canals can be optimised.

Three Ways to Improve Reticulation in Water Canals

Reticulation requires a high number of quality control mechanisms. Water canals must be healthy to ensure the water is suitable for a relevant purpose, and all steps should be taken to detect any issues in the treated water. However, most of the issues water managers deal with in the industry are hard to be detected by humans. Hence, integrating technology is a mandatory requirement. Here are three ways reticulation in water canals can be improved.

AI and IoT to Detect Water Canal Leakages

Water canals are prone to leakages where they are not appropriately maintained. In this regard, IoT sensors incorporated into each canal can detect whenever a problem starts to form within. Various types of IoT sensors based on temperature, sound, or others are implemented to collect different degrees of data. Using AI and ML capabilities, IoT can help predict future anomalies which could lead to water leakages. Hence, this time-consuming process can be automated with advanced technologies instead of manually sending out teams to do routine checks. In a wide network of water canals, integrating such tools allow water managers to pinpoint the exact location of the leakage and address it as soon as possible. This ensures that the leakage count can be measured and does not leave room for much contamination. Further integrating technologies such as GIS allows managers to monitor the entire canal network spread across the whole town, city or state in one go, thereby effectively prioritising maintenance based on its criticality tags.

Incorporating Big Data Analytics to Receive Hidden Insights and Meet Quality Control Mechanisms

Big data analytics is a significant advantage for water asset managers. Since many devices are incorporated into water canals to monitor their lifecycle and performance, an enormous amount of data is consistently generated. Water asset managers can unlock the true benefit of producing so much information when compiled and centralised into one location. For instance, big data analytical capabilities have the potential to understand consumer patterns. To put this into context, consider the population of a country. While they will continue to grow with each passing year, it does not mean that they are equally scattered in similar amounts in each town, city or state. Big data analytics considers which parts of a country have a larger population and directs water in the reticulation network accordingly. Hence, instead of simply distributing water in equal amounts to all regions, it sends water according to the number of inhabitants. As a result, technology allows water managers to provide equitable practices, ensuring every drop of water is used with care. Additionally, big data analytics plays a crucial role in ensuring the treated water that is recycled is safe for either drinking or other purposes. By considering what quality standards should be met in the industry, big data helps managers to monitor and assess whether recycled water is safe.

Using Digital Twins to Engineer, Manufacture and Construct Robust Wastewater Canals

With digital twin and simulation technology, designers and engineers can test various prototypes before finalising a water canal. Since all this is done virtually, asset managers will not be required to waste energy or finances in the testing stage. By carrying out multiple tests during the engineering phase, water asset managers can take essential variables, such as weight, size and others, which can withstand any weather or other adverse conditions. This also gives engineers leeway to test sustainable construction modes to combat climate change and reduce carbon emissions.

Industry 4.0 Is the Answer You Seek

Utility managers always find themselves in a situation wondering how reticulation can be optimised in water canals. Industry 4.0 is the most reliable answer that houses so much power and provides a range of benefits for the public. Whether it is AI, ML, GIS, big data analytics or digital twin, finding a compact solution that offers all of it is the best way to optimise the overall reticulation efforts in water canals. Remember that most of these technologies work together; hence, the more advanced technologies infused, the better the results and insights generated.