Around the globe, factories in the various industries release more than 300 million tons of industrial waste to the environment. The problem starts with the fact that around 80% of such waste is released even without a proper waste treatment mechanism. These waste directly pollute the lakes, rivers, groundwater, air and soil at a greater scale. The scariest part is yet to come! According to the reports, industrial pollution is the main reason for over 9 million premature deaths every year. This is where the need for a strategic industrial pollution control framework starts.

In this article, we walk you through some outstanding ways to reduce industrial pollution for your factory.

Understanding the Causes of Industrial Pollution

- First, let’s understand what this industrial pollution is. It occurs when factories discharge harmful waste as byproducts of their industrial processes into the air, water, or land. As much as industries contribute to the world’s economy, industrial pollution has become a massive challenge for the environment and human health.

- How does industrial pollution occur? They are not limited to one of a few causes. It mainly happens due to the burning of fossil fuels like coal, oil, and gas. Synchronous with the operational process, it tends to produce smoke and greenhouse gases. If we look into a distinct modality of pollution, it stems from factories releasing untreated wastewater, which gets mixed into the rivers and lakes. There are some solid wastes such as plastics, metals and chemicals, which are administratively infeasible.

- Some factories employ old machines and unsafe production methods during the production framework, and that makes pollution 10 times worse. No matter whether it is soil, air or water, if factories are not mindful of disposing of their waste in a proper way, it always negatively impacts the environment.

The Best Ways to Reduce Industrial Pollution

Adopting Cleaner Production Processes

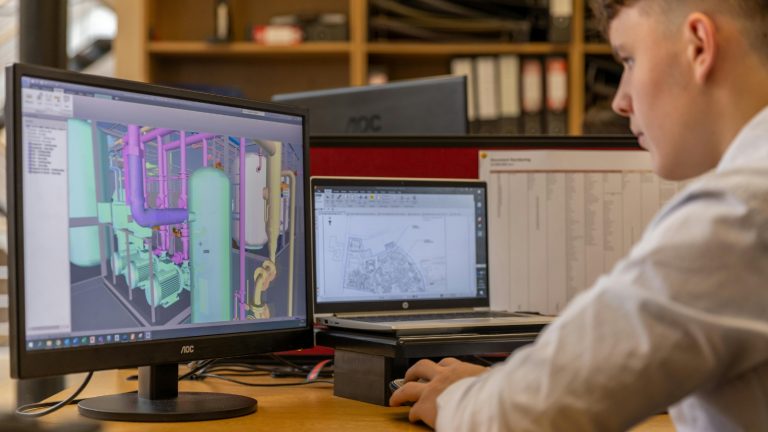

‘Prevention is always better than a cure.’ This theory applies to the industrial world as well. Instead of seeking prevention methods for the waste production and pollution, the industries can start from the roots. This means it is advisable for the factories to make refinements to their original production processes and find ways to reduce pollution. The best way to fulfil this is by using cleaner and safer production methods. The latter would not be a challenge if they opt for technology that generates less waste and fewer emissions. For example, there are modern machines that can use raw materials more efficiently, and these types of advanced equipment decrease the potential of factories releasing harmful gases.

The brighter side of integrating cleaner production processes goes beyond that, as it helps companies save money due to their utilisation of less energy and water. This is simply putting the full stop for industrial pollution before it actually begins.

Implementing Wastewater Treatment Systems

There is no factory which does not release dirty water into nearby rivers and lakes. The dark side of this is that this water has toxic content, such as harmful chemicals, heavy metals or oil. This is why it is necessary to stop pollution, and it will be a great strategy for the factories to install wastewater treatment systems.

The prime focus of installing them is to remove the toxins hidden in the water before releasing them into the environment.

As the robust wastewater treatment processes remove the toxicity levels from the sewage, it will not harm fish, plants, or people. Since the industrial world has to walk through a stringent landscape of environmental laws, implementing such a robust strategy will help it with regulatory compliance.

Switch to Renewable Energy Sources

As per the reports coming from the industrial world, many industries still burn coal, oil, or gas for power. It is not a secret that these fuels release harmful gases that pollute the air and catalyse atmospheric and climatic shifts.

In the event that they foresee taking down the pollution to a lower level, they must alleviate ecological pollution burdens. This is why modern factories have started using some renewable energy, like solar, wind, or hydropower, in their operational ecosystem.

It is not a case of releasing smoke or dangerous gases when it comes to these sources. This is why many industries are interested in switching to renewable energy. In one way, the latter keeps the production process and after effects cleaner, safer, and in another way, it offers more sustainability for future generations.

Improve Energy Efficiency

Utilising energy wisely is another versatile strategy for the factories to control pollution. The whole point here is that it takes down the fuel amount needed for a machine or equipment to function.

When they utilise less fuel, they tend to require less energy. It is noticeable that using LED lights, efficient motors, and smart energy systems paves the way for factories to save power.

With less fuel burned comes less air pollution. The energy efficiency not only saves the environment, but it also helps industrial companies save costs.

Reduce, Reuse, and Recycle (3Rs)

On the path of seeking the best solutions to pollution control, the 3Rs have gained a reputation as a simple way to fight against it. 3Rs starts with reducing, and it simply talks about making less waste from the start.

Then comes the reusing, and it means instead of throwing the materials after one use, finding some mindful ways to use them over and over. As the last phase, recycling is the process, which factories transform waste into useful products.

If they end up with metal scraps, they can find a method to melt them and reuse them for a better purpose. Not to mention that these initiatives kick off industrial pollution control while saving resources. This is where the sustainability begins.

Install Air Pollution Control Devices

It is indeed problematic that factories dispense smoke and dust into the air on a regular basis. It is a wise strategy to install special air management devices in order to capture how much polluted air is released into the environment per day.

Based on this data, companies and industrial plants can implement prevention strategies and precautions to reduce the air pollution levels.

Inbuilt with robust air filters, scrubbers, and electrostatic systems, these devices have the capacity to catch harmful particles before they get mixed into the air. With such a straightforward method, the industrial world can keep a safe distance from air quality laws and penalties.

Promote Circular Economy Models

It has been established as a normative procedure among industries to implement the circular economy, as the latter contributes to the attenuation of pollutant levels with its ability to keep materials in use for a long time.

Instead of making, using, and throwing away products, industries can design items that can be repaired, reused, or recycled.

This strategy turns down waste and pauses new pollution.

Technologically Encouraging Industrial Pollution Control to Keep Sustainability Alive

As you can see, industrial pollution control does not come cheaply as it covers a variety of production processes from their roots to the end. What if you could cover every aspect of your production under one dashboard? Tigernix software solutions come with the capacity to offer insights for processes, logistics, and designs, as well as sustainability initiatives. This is where our solutions support your pollution control strategies, analysing data for potential pollution factors. With such robustness, you can easily keep your sustainability promise alive.