This is why we explore the four main types of Digital Twin used in the water industry and their impact on asset management.

Understanding the Potential of Digital Twin Technology

- It is not a lie to say that this technology holds immense potential across various industries. Not only in Australia but also in other countries, it is revolutionising how businesses and organisations design, operate, and maintain complex systems.

- This technology involves creating a digital replica of a physical object, process, or system, allowing for real-time monitoring, analysis, and simulation. The digital twin mirrors the physical entity by using sensors and data collection tools, continuously updating itself with real-world data. This creates a dynamic and accurate representation that helps predict outcomes, optimise performance, and prevent potential issues.

- Let us explain where the digital twinning process starts. It actually begins with data collection from the physical asset, followed by creating a virtual model that mimics the physical counterpart. The virtual model gets fed with real-time data from sensors on the physical object, allowing it to reflect the current state of the object accurately. After analysing this data, businesses can optimise operations, improve product quality, and enhance decision-making.

- In mega infrastructure-related asset management, Digital Twin backs up companies to simulate the functioning of such asset processes, test new designs, and foresee equipment failures before they occur. This means the application of the latter is not limited to one particular sector. It can be modified and customised as per requirements.

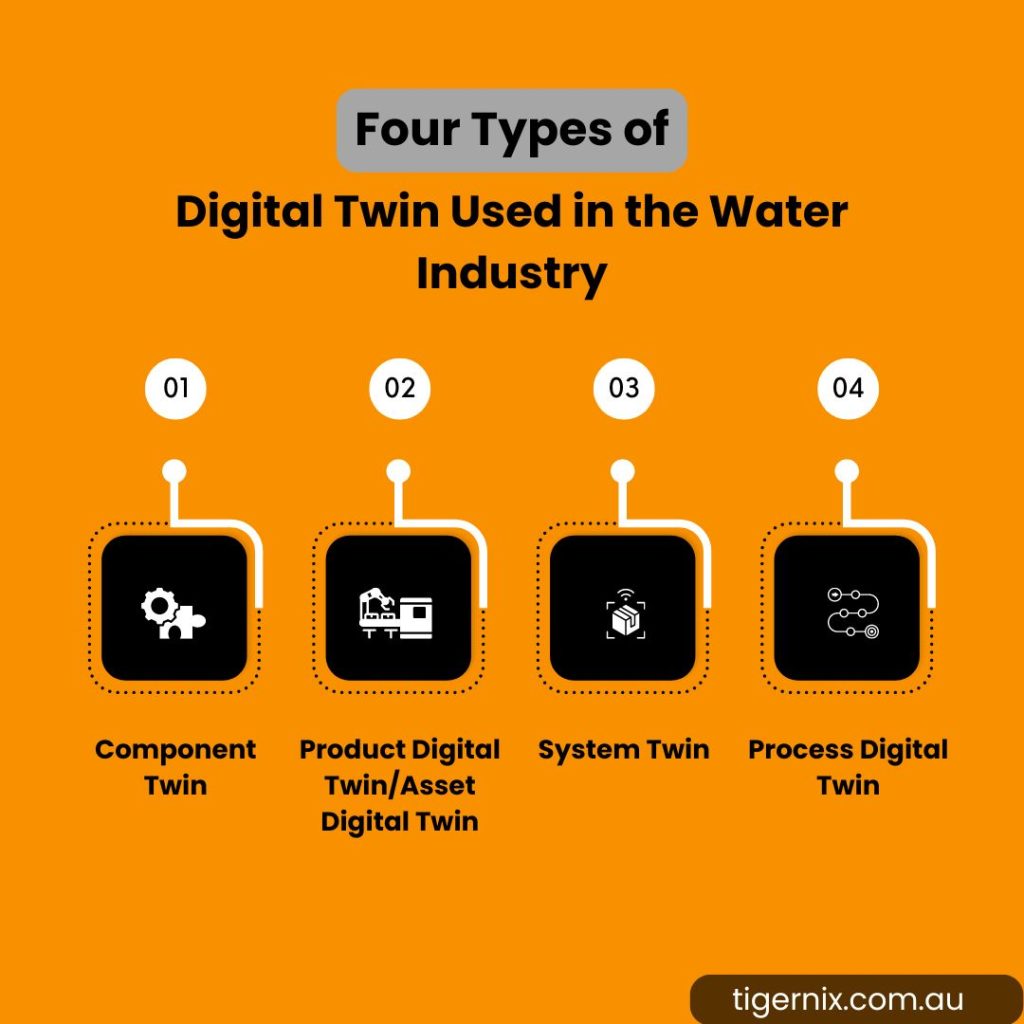

Types of Digital Twin Used in the Water Industry

It is a common thing for water treatment facilities to use digital twin in various stages of operations to enhance efficiency. The primary value of digital twin lies in optimising processes, leading to advancements like smart automation and predictive analytics. However, as we mentioned before, different types of digital twin exist, varying in the scale of coverage. In the section below, we discover the four main types of Digital Twin models.

Component Twin

The Component Twin creates a digital replica of these individual parts, allowing for real-time monitoring and analysis of their functionality. By doing so, water treatment facilities can track the performance of each component, ensuring that everything operates smoothly. For example, the digital twin of a valve in the water treatment plant can help operators monitor its opening and closing rates, detect any irregularities, and predict when it might need maintenance. This advanced approach prevents sudden failures that could disrupt the water treatment process.

If they opt to use Component Twin, water treatment facilities can enhance their ability to monitor and maintain their systems, ensuring consistent water quality and system stability. This technology not only helps keep the treatment process running efficiently but also supports the long-term sustainability of water resources by enabling better decision-making and maintenance practices.

Product Digital Twin, or Asset Digital Twin

Unlike Component Twin, which focuses on individual parts, Asset Twin brings together multiple components to create a comprehensive model of a larger piece of equipment or system. In the water treatment industry, this means combining data from sensors on pumps, valves, and filters to simulate and monitor the entire water treatment process.

If simplified, the digital twin captures how these parts interact, helping operators understand the system’s overall efficiency and performance. For instance, by using an Asset Twin of a water pump, engineers can monitor how well the pump works in conjunction with the valves and sensors that regulate water flow and pressure.

The digital twin analyses this data to identify any inefficiencies or potential failures before they occur. This real-time insight allows for proactive maintenance, reducing the mean time between failures and the mean time to repair.

System Twin

This type of Digital Twin, also known as a Unit Twin, represents how different assets like pumps, filters, and chemical dosing units work together as a functional unit. Since this provides a large-scale overview of the plant, System Twin allows operators to test various system configurations and optimise the effectiveness of the water treatment process.

For example, a System Twin might combine data from all the components involved in energy supply, such as pumps, motors, and control systems. This digital model paves the way for the plant to monitor energy consumption in real time, detect inefficiencies, and explore ways to reduce energy use without compromising water quality.

The System Twin also allows operators to simulate different scenarios, such as changing the order of operations or adjusting the flow rates, to see how these changes affect the overall performance of the plant. As you can see, this capability helps identify new enhancement opportunities, such as introducing more energy-efficient equipment or optimising chemical usage to reduce costs.

Process Digital Twin

The latter technology connects individual system twins, such as those for pumps, filtration units, and chemical dosing systems, to create a comprehensive view of the entire water treatment process. This way, Process Twin allows operators to analyse how different systems work together, helping them understand the overall efficiency and effectiveness of the water treatment plant.

Plus, Process Twin can simulate the impact of adjusting the rate at which raw water enters the system, changing the temperature during treatment, or modifying the chemical dosing. These simulations provide valuable data on how these changes affect the final water quality and system performance without actually disrupting the physical process.

This capability allows operators to test different strategies and business hypotheses safely and efficiently. Not to mention that this will ensure any adjustments made to the treatment process will improve performance and not compromise water quality.

Creating the Digital Twin Model that Suits Water Industry Operations

You may now understand that the right Digital Twin model can transform water industry operations while providing valuable insights and optimising processes at the same time. If you opt to work with a reputable partner, you can develop a Digital Twin model tailored to your specific requirements, ensuring that your operations are both efficient and sustainable. For this, you need to make the smart choice to collaborate with an expert who understands the deep holes of water management technology in Australia.