Did you hear that Australia plans to raise limits on PFAS (Per- and polyfluoroalkyl substances)in drinking water?

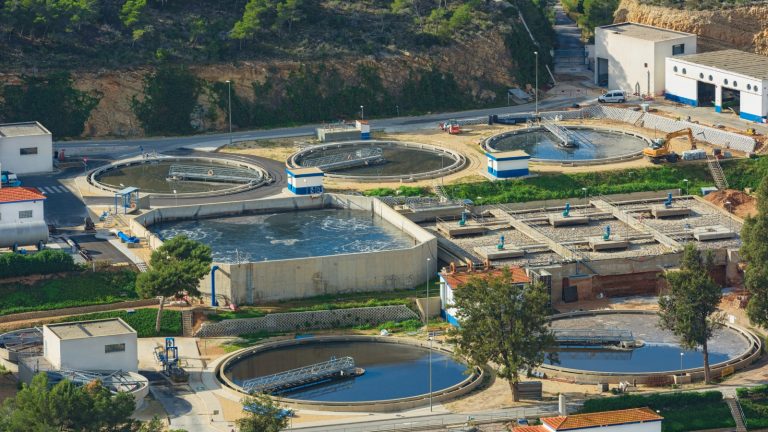

Water is our life, but it takes a chain of complicated steps at water treatment plants to be assured that it is truly safe to drink. When it comes to producing safe and clean water, coagulation in water treatment is one of the most important steps.

This process removes suspended particles, colloids, and other impurities, making the water cloudy or unsafe. It works by destabilising them. This way, they come together to form larger particles, which then can be more easily separated during sedimentation and filtration.

Understanding how this works is essential to preserving drinking water safety and to maintaining the efficiency of the water purification process. This article covers everything about coagulation in water treatment.

Understanding Coagulation in Water Treatment

Coagulation in water treatment is a chemical treatment process in which small colloidal particles in suspension are made to agglomerate by bridging the charged edges of the particles with multivalent ions.

When raw water contains common negatively charged particles, such as colloidal matter, and if one adds a positive charge, the negative particles repel each other , keeping them in suspension. That charge must be balanced with coagulants, substances that reduce the stability of charged particles through offering something to stick to.

Once they are neutralised, the particles will coagulate into microflocs. This is essential for turbidity removal and enhancing the clarity of water, which in turn increases the efficiency of other subsequent operations such as flocculation and sedimentation.

When it comes to effective coagulation, this not only enhances aesthetic characteristics but also lowers pathogens and organic material for safe drinking water.

Key Takeaways

- Coagulation is the process that brings suspended particles together and clarifies water during treatment.

- Correct choice and dosage of water treatment chemicals results in successful floc formation.

- Use monitoring, exemplified by the Jar Test, to maximise the safety and efficiency of coagulation.

- Coagulation, flocculation, sedimentation, and filtration followed by disinfection makes drinking water safe.

Key Chemicals Used in Coagulation

- Alum (aluminium sulfate) is the most common and economical chemical used for this purpose.

- Another coagulant is Ferric chloride, which may be used for water with high turbidity or colour.

- Artificial coagulants, such as Polymeric coagulants, have comparable performance on similar dosing and provide better floc strength.

Factors Affecting Coagulation Efficiency

- The pH adjustment is important because a coagulant usually acts best in a particular pH range.

- Reaction rates are also influenced by water temperature, as cold water will slow floc formation.

- Dosage of chemicals should be adequate to avoid dispersion of particles but not in such a concentration as to break flocs.

- The intensity of a mixer , together with the mixing time, impacts particle-to-particle collisions and agglomeration.

Coagulation Process Steps

The coagulation process in a water treatment plant can be viewed as a multistage process for effective removal of suspended particles. These steps are highly regulated for turbidity removal and safe water purification.

Step 1- Rapid Mixing

The first step is rapid mixing. After adding the coagulant to water, it is mixed at a high concentration so that mixing mechanisms work to distribute the chemicals widely for charging of particles.

Without good mixing, not all particles will come into contact with the coagulants, and hence the coagulation efficiency decreases. This step usually takes anywhere from several seconds to a couple of minutes, depending on water volume and the type of coagulant used.

Fast mixing is used to create the right environment for floc formation by rapidly and uniformly dispersing the coagulant. Likewise, the destabilised particles collide with each other and start forming micro-floc while facilitating an improvement in water clarity improvement.

Step 2- Floc Formation

After a short mixing time, the system proceeds to floc formation, where still unstable particles come together in such a way as to create a microfloc. This step depends on the coagulant–particle reaction and gentle stirring as physical motion.

Once the micro-flocs develop, the water may look a little cloudy, but only temporarily. The flocculation stage is particularly important to attain maximum turbidity removal, because floc really forms well and grows into large aggregates only at properly adjusted flocculation conditions.

In this context, controlled mixing promotes collisions and adhesion between micro-flocs without significantly dispersing them in the water, for the subsequent water purification process and cleaning.

Step 3- Floc Growth

While the floc is developing, water is slowly stirred to bring the micro-flocs into contact, as they can ‘stick’ and grow together into bigger, heavier flocs. This phase is called flocculation.

Shear must be controlled quite precisely: too much turbulence disperses flocs, and not enough mixing slows growth. The larger the size and the higher the strength of these flocs, the more efficient the sedimentation will be.

Good floc growth is necessary to capture a maximal amount of suspended particles so that there can be optimum efficiency in sedimentation and filtration devices. This process improves, and it increases the overall water clarity improvement, as well as helping to ensure drinking water safety.

This is why it has become an indispensable part of coagulation in water treatment.

Step 4- Sedimentation

During sedimentation, larger flocs fall to the bottom of the water under gravity and remove most suspended material. Water is received into sedimentation tanks, and the floc slowly settles to the bottom, forming sludge that is periodically scraped off.

Overall, this phase is closely related to a pretreatment of high importance: Through this step, a significant portion of turbidity can be removed prior to filtration.

When the sedimentation works well, the downstream filtration processes fewer particles, and that is better for the efficiency of the plant. Water that settles well at this stage is cleaner, safer drinking water and treated water, making it ready for the further stages of treatment.

It can be seen that coagulation in water treatment is essential in the overall water purification process.

Step 5- Filtration (Optional Step)

Water is also commonly filtered after sedimentation. Filters, whether sand and multimedia or membrane, function to retain any leftover flocs or smaller contaminants.

It is used alongside coagulation in water treatment, ensuring that the treated water meets the requirements for safety and clarity. It also prevents clogging of distribution systems and keeps drinking water safety at a high level.

Water treatment plants combine coagulation, flocculation, sedimentation, and filtration to remove substances that cause cloudy or coloured water and to physically remove pathogens from the water by settling or retaining them in a filter.

The latter completes the process of turning raw source water into clean drinking water.

Testing and Monitoring Coagulation

It is compulsory to maintain regular checks and control to prevent the failure of a coagulation process in water treatment. The method used in the laboratory to simulate on a small scale the process of coagulation is known as the Jar Test.

The type and dose of the coagulant are manipulated by operators to find an optimum condition for maximum turbidity removal. Cycling pH and particle counts are monitored to maintain performance.

Moreover, ongoing testing ensures safe drinking water and helps ensure compliance with E.P.A. regulations. Properly-timed coagulation also enhances downstream processes, including sedimentation and filtration, which in turn maximise water treatment plant efficiency and ensure consistently high-quality drinking water for the consumers.

How Tigernix Smart Water Software Optimises Coagulation in Water Treatment

Tigernix Smart Water Asset Software enables the coagulation stage of water treatment to be optimised through real-time measurement of water quality parameters like turbidity, pH, and particle count.

Its predictive analytics suggest exact coagulant doses and mixing times, cutting chemical waste and enhancing floc creation. With real-time alerts and historical data analysis, operators are better able to optimise processes, improve clarity, and maintain a consistent level of safety in drinking water.

This leads to savings, better productivity, and predictable treatment results.

Call for a free demo.

Tigernix-Making Way for Safe Drinking Water

Understanding the Role of Coagulation in Optimising Water Purification Processes

Coagulation is a core process in water treatment that enables the production of potable water. It eliminates suspended solids, neutralises particle charges in water, and promotes the flocculation of particles for easier sedimentation. Correct choice of water treatment chemicals and keeping track of the pH for using Jar Tests is essential for adequate coagulation.

Together with flocculation, sedimentation, and filtration, this process ensures the safety of drinking water as well as an efficient treatment process.

This is why the knowledge of coagulation and optimisation is critical for any water treatment plant that is serious about making high-quality water.

FAQs About Coagulation in Water Treatment

Coagulation in water treatment is the process of adding chemicals, such as alum, to water to neutralise particle charges. This allows suspended solids and colloids to clump together into flocs, which can be removed through sedimentation and filtration. It is essential for turbidity removal, water clarity improvement, and ensuring drinking water safety.

The most common water treatment chemicals used for coagulation are alum (aluminum sulfate), ferric chloride, and polymeric coagulants. These chemicals help destabilise particles so they can form flocs. Proper selection and dosage are crucial for effective turbidity removal and maintaining drinking water safety.

The Jar Test is a laboratory procedure that simulates the coagulation process on a small scale. It helps water treatment operators determine the optimal coagulant type and dosage for maximum turbidity removal. Using the Jar Test ensures efficient floc formation, sedimentation, and filtration in the water treatment plant.

pH plays a critical role in coagulation in water treatment because coagulants work most effectively within specific pH ranges. If water is too acidic or alkaline, floc formation can be weak, reducing turbidity removal and overall water clarity improvement. Monitoring and adjusting pH ensures that flocs form properly, improving sedimentation efficiency and maintaining safe, clean water.

Coagulation is important because it removes suspended particles, improves water clarity, reduces pathogens, and enhances sedimentation and filtration efficiency. It also lowers chemical use in downstream processes and ensures compliance with water safety standards. Coagulation is essential for producing clean, safe water in every water treatment plant.